How can I translate the catalog into different languages?

- You must first install the translate extension of Google Chrome on your browser from here.

(If you are using another browser, install that extension of translate )

- Now catalog from here.

- After opening the catalog, select the translate option from the top (three vertical dots).

- Now choose the desired language and enjoy the products and services of our company

About Us

Serkeft Chemicals Company

The Company was established in Zakho during the year of 2020 after five years of working in Turkey since 2015 for producing different types of chemical admixtures for concrete mixtures & cement.

The company has qualified staff ( International & Local ) of relevant specialties who are working in the factory premises furnished with sophisticated equipment for producing of high quality admixture materials.

(types and use of various products are indicated in the catalogue pages)

It has also over of 20 years' experience is producing & supplying of concrete mixtures through a number of modern batching plants located in Zakho & Erbil.

With the power of producing its own raw materials, Serkeft Chemical has managed to double its turnover every year since its establishment.

It offers innovative products with self-developed raw materials to manufacturers of cement and concrete as well as manufacturers of chemical admixture in Iraq and neighboring countries.

Innovation & Trust

New Generation Concrete Chemicals

HYPER W303

POLYMER BASED

SUPER PLASTICIZING

DRYING RETARDER

HIGH-RANGE WATER REDUCING

your innovation

solution partner

REVISION DATE :17/04/2022

REVISION NUMBER: 18/04/2023

Product Definition

HYPER W 303 is a chemical admixture which, without affecting the consistency, permits a high reduction in the water content of a given concrete, or which, without affecting the water content, increases the slump/flow considerably, or produces both effects simultaneously.

Uses

• For improving workability and placing of conventional fresh concrete.

• For improving placing of concrete designed for slabs.

• Ready-mixed concrete production.

• Normal reinforced concrete elements such as column, shear wall and beam.

• Drying retarder in hot weather , it helps to delay the freezing of concrete for about 2 hours

• For concrete transported over long distances

Advantages and Properties

- HYPER W 303 is a modified polymer based general purpose chemical admixture designed for improving workability of fresh concrete without increasing water content.

- HYPER W 303 increases the flowability of fresh concrete without causing segregation.

- Provides easiness in mixing, transporting, placing and vibration works.

- Decreases the permeability and improves the durability of hardened concrete.

- HYPER W 303 is an appropriate chemical admixture to use in mixtures containing mineral admixtures such as silica fume, fly ash and ground granulated blast furnace slag.

- Does not contain chloride or any other substances that may cause corrosion

Application Details, Suggestions and Warnings

- HYPER W 303 should be added to the mixing water or fresh concrete during mixing process. In case of an addition to fresh mixture, additional mixing time should be applied. Hyperw303should not be added to the dry mixture.

- As the dosage of the chemical admixtures is greatly influenced from cement type, properties of the concrete ingredients and mix design, it is recommended that the optimum dosage of admixture should be determined on trial batches.

- HYPER W 303 is generally compatible with the Portland cement types described in TS EN 197-1. In addition, it can be used in concrete mixes containing mineral admixtures such as silica fume, fly ash and ground granulated blast furnace slag. However, since the presence of mineral admixtures in the mixture greatly influences the required dosage of the admixture for a specified target or performance, the optimum dosage of HYPER W 303.

- There is no known incompatibility with the other type of chemical admixtures and can be used with the others in the same mixture. In case of the combined usage, the different types of chemical admixtures should not be mixed together and be used separately. Please contact R&D department of Serkeft for further information.

- Overdose may cause segregation and excessive increase in setting time. In case of an excessive increase in setting time, protective measures should be applied against surface and/or shrinkage cracks and the fresh concrete surface should be kept wet. Standard curing procedures and protective measures for fresh concrete shouldbe followed.

Cleaning of Tools

- Concreting tools contact with HYPER W 303 can be easily cleaned with water.

Packaging

25 kg Plastic drum

1000 kg IBC

Bulk Delivery

Recommended Dosage

The recommended dosage rate of HYPER W 303 for general concreting operations is between (0.8%-1.5%) of the weight of binding material (cement + mineral admixture). HYPER W 303 acts as a superplasticizer in high dosage rates with an appropriate cement and mix design. The appropriate dosage should be determined on trial batches. Please contact SERKEFT R&D department for technical support

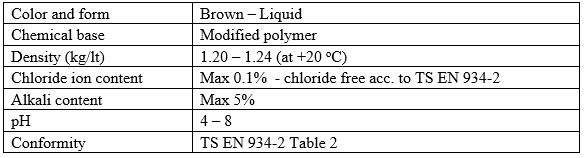

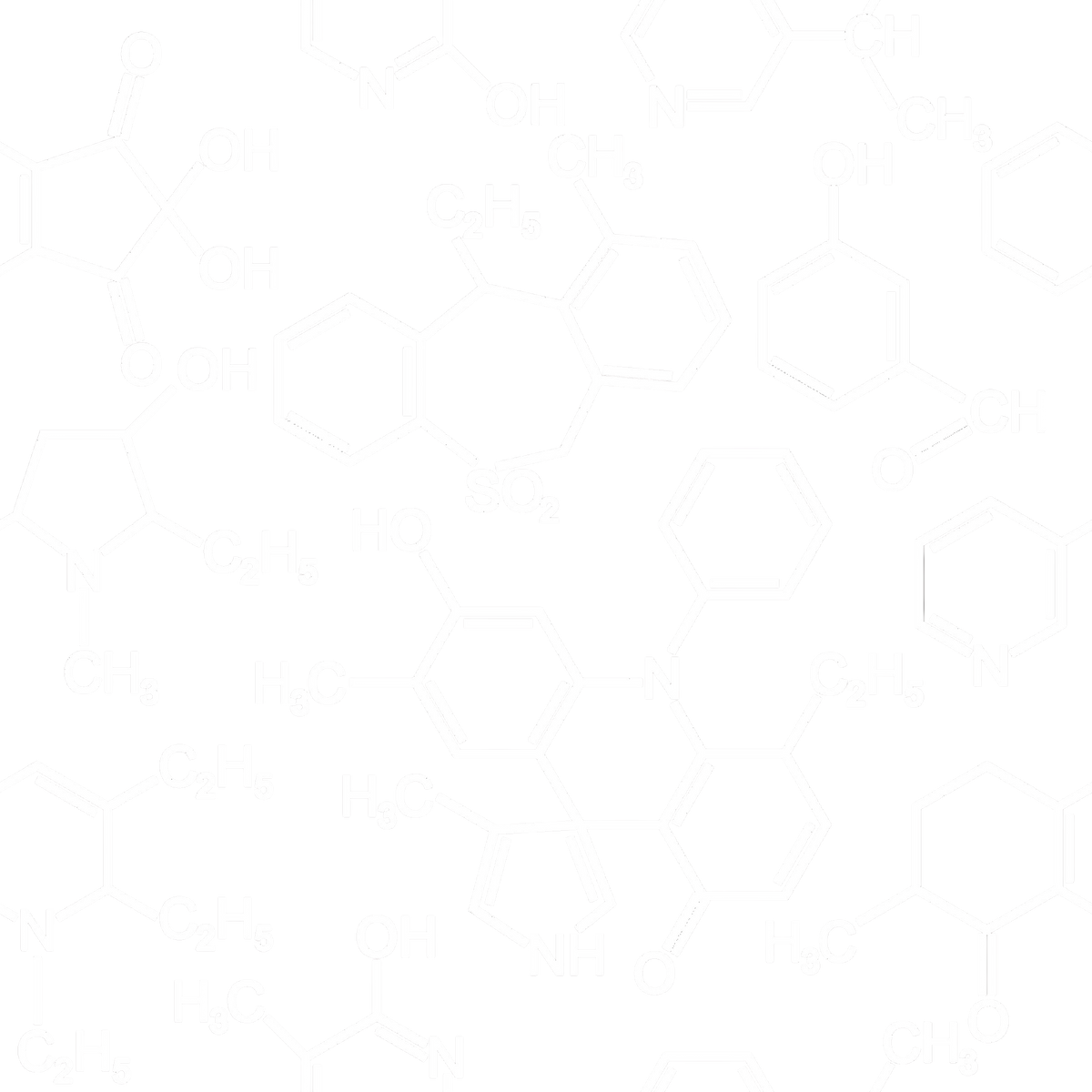

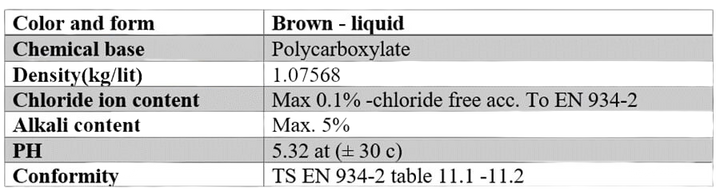

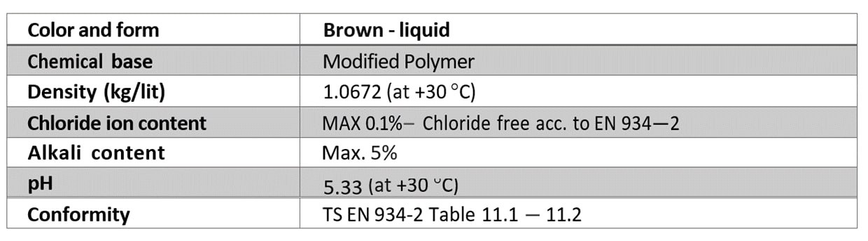

Technical Properties

Storage and Shelf Life

Shelf life of HYPER W 303 is 12 months when stored in its original package and recommended storage conditions. HYPER W 303 should be stored in dry conditions between +5 ℃ and +35 ℃. It should be protected from direct sunlight and frost.

Security and Health

In case of contact with skin, wash with clean water. In case of contact with eye, wash with clean water. Eye contact should be medical consulted immediately. For further information please refer to Material Safety Data Sheet (MSDS)

Legal Liability

The technical recommendations in this product data sheet are based on the experimental studies performed on reference concrete mixtures designed in the R&D laboratories of SERKEFT. The results may not be applicable to different concrete mixtures produced with different materials than the ones used in the experiments in SERKEFT. All customers and users are required to determine the appropriate SERKEFT products for their intended use and to test the suitability of SERKEFT product for their application. Please contact SERKEFT for the appropriate product selection and usage details. SERKEFT is not responsible for the improper usage of the products.

CAST CT 600

POLYMER BASED

SUPER PLASTICIZING

HARDINING ACCELERATOR

HIGH WATER REDUCTION

SELFE COMPACTING CONCRETE

your innovation

solution partner

REVISION DATE :15/02/2022 REVISION NUMBER: 18/04/2023

Product Definition

CAST CT 600 is a chemical admixture which, without affecting the consistency, permits a high reduction in the water content of a given concrete, or which, without affecting the water content, increases the slump/flow considerably, or produces both effects simultaneously

Uses

CAST CT 600 is recommended for use in the applications and purposes below.

• For improving workability and placing of conventional fresh concrete.

• For improving placing of concrete designed for slabs. • Ready-mixed concrete production.

• Normal reinforced concrete elements such as column, shear wall and beam.

• concrete work requiring early formwork removal.

• chemical admixture (CAST CT 600) is hardening accelerator recommended for use in concrete work requiring early formwork removal. standard compressive strength of concrete after 18 hours is 8%, As temperatures drop, concrete sets more slowly, takes longer to finish, and gains desired strength less rapidly

Advantages and Properties

- CAST CT 600 is a modified polymer based, general purpose chemical admixture designed for improving workability of fresh concrete without increasing water content.

- CAST CT 600 increases the flowability of fresh concrete without causing segregation. Provides easiness in mixing, transporting, placing and vibration works.

- Decreases the permeability and improves the durability of hardened concrete.

- CAST CT 600 is an appropriate chemical admixture to use in mixtures containing mineral admixtures such as silica fume, fly ash and ground granulated blast furnace slag.

- Does not contain chloride or any other substances that may cause corrosion.

Application Details, Suggestions and Warnings

- CAST CT 600 should be added to the mixing water or fresh concrete during mixing as silica case of an addition to fresh mixture, additional mixing time should be applied. CAST CT 600 should not be added to the dry mixture.

- As the dosage of the chemical admixtures is greatly influenced from cement type, properties of the concrete ingredients and mix design, it is recommended that the optimum dosage of admixture should be determined on trial batches.

- CAST CT 600 is generally compatible with the Portland cement types described in TS EN 197-1. In addition, it can be used in concrete mixes containing mineral admixtures such as silica fume, fly ash and ground granulated blast furnace slag. However, since the presence of mineral admixtures in the mixture greatly influences the required dosage of the admixture for a specified target or performance, the optimum dosage of CAST CT 600

- There is no known incompatibility with the other type of chemical admixtures and can be used with the others in the same mixture. In case of the combined usage, the different types of chemical admixtures should not be mixed together and be used separately. Please contact R&D department of Serkeft for further information.

- Overdose may cause segregation and excessive increase in setting time. In case of an excessive increase in setting time, protective measures should be applied against surface and/or shrinkage cracks and the fresh concrete surface should be kept wet.

- Standard curing procedures and protective measures for fresh concrete should be followed.

- The recommended dosage rate of CAST CT 600 for general concreting operations is between 0.8% - 1.5 % of the weight of binding material (cement + mineral admixture). CAST CT 600 acts as a superplasticizer in high dosage rates with an appropriate cement and mix design. The appropriate dosage should be determined on trial batches. Please contact Serkeft R&D department for technical support.

Cleaning of Tools

- Concreting tools contact with CAST CT 997 can be easily cleaned with water.

Packaging

25 kg Plastic drum

1000 kg IBC

Bulk Delivery

Recommended Dosage

The recommended dosage rate of CAST CT 600 for general concreting operations is between 0.8%-1.5% of the weight of binding material (cement + mineral admixture). CAST CT 600 acts as a superplasticizer in high dosage rates with an appropriate cement and mix design. The appropriate dosage should be determined on trial batches. Please contact SERKEFT R&D department for technical support.

Technical Properties

Storage and Shelf Life

Shelf life of CAST CT 600 is 12 months when stored in its original package and recommended storage conditions. CAST CT 600 should be stored in dry conditions between +5 ℃ and +35 ℃. It should be protected from direct sunlight and frost.

Security and Health

In case of contact with skin, wash with clean water. In case of contact with eye, wash with clean water. Eye contact should be medical consulted immediately. For further information please refer to Material Safety Data Sheet (MSDS).

Legal Liability

The technical recommendations in this product data sheet are based on the experimental studies performed on reference concrete mixtures designed in the R&D laboratories of SERKEFT. The results may not be applicable to different concrete mixtures produced with different materials than the ones used in the experiments in SERKEFT. All customers and users are required to determine the appropriate SERKEFT products for their intended use and to test the suitability of SERKEFT product for their application. Please contact SERKEFT for the appropriate product selection and usage details. SERKEFT is not responsible for the improper usage of the products.

HEZ X 206

POLYMER BASED

SUPER PLASTICIZING

HIGH WATER REDUCTION

SELFE COMPACTING CONCRETE

HIGH STRENGTH

your innovation

solution partner

REVISION DATE :02/06/2022 REVISION NUMBER: 18/04/2023

Product Definition

HEZ X 206 is polycarboxylate based, high-range water reducer / superplasticizer type of chemical admixture designed for the production of very flowable concretes (S5 workability class) or self- compacting concretes. HEZ X 206 provides very high flowability and slump retention performance.

Uses

HEZ X 206 is recommended for use in the applications and purposes below.

• Concrete production in very high workability classes.

• Self-compacting concrete production.

• Ready-mixed concrete production.

• Drying retarder in hot weather

• Concretes designed for sections having closely spaced and congested reinforcing steel.

• Concrete production in low water to cement ratio without slump loss.

• High strength concrete production

Advantages and Properties

- HEZ X 206 is a modified polycarboxylate based, high-range water reducer, superplasticizer type of chemical admixture designed for making very flowable concrete and selfcompacting concrete.

- Thanks to its specially designed and optimized chemical structure it has a very effective dispersion effect of cement particles and prevents the flocculation. This mechanism makes HEZ X 206 a very effective dispersant to obtain self-compatibility in very low water to cement ratios.

- Thanks to the appropriate combination of polycarboxylate ether and triethanolamine compounds, HEZ X 206 improves the early strength.

- A water reduction up to 30%-35% by satisfying the target workability can be obtained through the appropriate usage of HEZ X 206 This significant amount of water reduction and decreased water to cement ratio results in increased early strength gain, increased ultimate strength, enhanced durability and the other beneficial properties associated with low water to cement ratio such as decreased chloride-ion penetration.

- Provides significant increase in workability without increasing the quantity of mixing water and hence procures considerable easiness in mixing, transporting, placing and compaction of fresh concrete.

- Improves the strength and durability by ensuring that the specified target consistency is achieved with lower water to binder ratios.

- It is non-chloride admixture and does not contain any compounds that may cause corrosion of reinforcing steel

Application Details, Suggestions and Warnings

- HEZ X 206 should be added to the mixing water. HEZ X 206 should not be added to the dry mixture.

- As the dosage of the chemical admixtures is greatly influenced from cement type, properties of the concrete ingredients and mix design, it is recommended that the optimum dosage of admixture should be determined on trial batches.

- HEZ X 206 is generally compatible with the Portland cement types described in EN 197-1. In addition, it can be used in concrete mixes containing mineral admixtures such as silica fume, fly ash and ground granulated blast furnaces lag. It should be noted that, the presence of mineral admixtures in concrete greatly influences the required dosage of the admixture for a specified target or performance. The optimum dosage of HEZ X 206 should be determined on trial batches

HEZ X 206 is not compatible with sulfonated naphthalene and sulfonated melamine based chemical admixtures. There is no known incompatibility with the other type of chemical admixtures and can be used with the others in the same mixture. In case of the combined usage, the different types of chemical admixtures should not be mixed together and be used separately. Please contact R&D department of SERKEFT for further information.

Cleaning of Tools

- Concreting tools contact with HEZ X 206 can be easily cleaned with water.

Packaging

20 kg Plastic drum

1000 kg IBC

Bulk Delivery

Recommended Dosage

The recommended dosage rate of HEZ X 206 is between 0.4 % - 2 % of the weight of binding material (cement + mineral admixture). The maximum water reduction and super plasticizing property increases as the dosage increases up to a saturation point. However, it should be considered that the required dosage varies with the type and amount of cement and mineral admixtures, water to binder ratio, properties of the other ingredients and the ambient temperature. Overdose may cause significant segregation and setting time increase. In addition, the required dosage of HEZ X206 to achieve a target performance will be different for each concrete mixture. The appropriate dosage should be determined on trial batches as it will not cause any segregation and/or undesirable side effects. It is known that there is a significant effect of C3A, SO3 content and fineness of cement on the appropriate dosage of HEZ X 206

Technical Properties

Storage and Shelf Life

Shelf life of HEZ X 206 is 12 months when stored in its original package and recommended storage conditions. HEZ X 206 should be stored in dry conditions between +5 ℃ and +35 ℃. It should be protected from direct sunlight and frost.

Security and Health

In case of contact with skin, wash with clean water. In case of contact with eye, wash with clean water. Eye contact should be medical consulted immediately. For further information please refer to Material Safety Data Sheet (MSDS).

Legal Liability

The technical recommendations in this product data sheet are based on the experimental studies performed on reference concrete mixtures designed in the R&D laboratories of SERKEFT. The results may not be applicable to different concrete mixtures produced with different materials than the ones used in the experiments in SERKEFT. All customers and users are required to determine the appropriate SERKEFT products for their intended use and to test the suitability of SERKEFT product for their application. Please contact SERKEFT for the appropriate product selection and usage details. SERKEFT is not responsible for the improper usage of the products.

HYPER W442

POLYMER BASED

SUPER PLASTICIZING

DRYING RETARDER

HIGH-RANGE WATER REDUCING

HIGH STRENGTH

your innovation

solution partner

REVISION DATE :17/04/2022

REVISION NUMBER: 18/04/2023

Product Definition

HYPER W442 is a chemical admixture which, without affecting the consistency, permits a high reduction in the water content of a given concrete, or which, without affecting the water content, increases the slump/flow considerably, or produces both effects simultaneously

Uses

HYPER W442 is recommended for use in the applications and purposes below.

• For improving workability and placing of conventional fresh concrete.

• For improving placing of concrete designed for slabs.

• Ready-mixed concrete production.

• Normal reinforced concrete elements such as column, shear wall and beam.

• Drying retarder, high protective properties in hot weather.

• For concrete transported over long distances

• High Strength Concrete Production

Advantages and Properties

- HYPER W442 is a modified polymer based general purpose chemical admixture designed for improving workability of fresh concrete without increasing water content.

- HYPER W442 increases the flowability of fresh concrete without causing segregation.

- Provides easiness in mixing, transporting, placing and vibration works.

- Decreases the permeability and improves the durability of hardened concrete.

- HYPER W442 is an appropriate chemical admixture to use in mixtures containing mineral admixtures such as silica fume, fly ash and ground granulated blast furnace slag.

- Does not contain chloride or any other substances that may cause corrosion

Application Details, Suggestions and Warnings

- HYPER W442 should be added to the mixing water or fresh concrete during mixing process. In case of an addition to fresh mixture, additional mixing time should be applied.

- HYPER W442 should not be added to the dry mixture.

- As the dosage of the chemical admixtures is greatly influenced from cement type, properties of the concrete ingredients and mix design, it is recommended that the optimum dosage of admixture should be determined on trial batches.

- HYPER W442 is generally compatible with the Portland cement types described in TS EN 197-1. In addition, it can be used in concrete mixes containing mineral admixtures such as silica fume, fly ash and ground granulated blast furnace slag. However, since the presence of mineral admixtures in the mixture greatly influences the required dosage of the admixture for a specified target or performance, the optimum dosage of HYPER W442.

- There is no known incompatibility with the other type of chemical admixtures and can be used with the others in the same mixture. In case of the combined usage, the different types of chemical admixtures should not be mixed together and be used separately. Please contact R&D department of Serkeft for further information.

- Overdose may cause segregation and excessive increase in setting time. In case of an excessive increase in setting time, protective measures should be applied against surface and/or shrinkage cracks and the fresh concrete surface should be kept wet.

- Standard curing procedures and protective measures for fresh concrete shouldbe followed

Cleaning of Tools

- Concreting tools contact with HYPER W442 can be easily cleaned with water.

Packaging

20 kg Plastic drum

1000 kg IBC

Bulk Delivery

Recommended Dosage

The recommended dosage rate of HYPER W442 for general concreting operations is between (0.8%-1.5%) of the weight of binding material (cement + mineral admixture). HYPER W442 acts as a superplasticizer in high dosage rates with an appropriate cement and mix design. The appropriate dosage should be determined on trial batches. Please contact SERKEFT R&D department for technical support.

Technical Properties

Storage and Shelf Life

Shelf life of HYPER W442 is 12 months when stored in its original package and recommended storage conditions. HYPER W442 should be stored in dry conditions between +5 ℃ and +35 ℃. It should be protected from direct sunlight and frost.

Security and Health

In case of contact with skin, wash with clean water. In case of contact with eye, wash with clean water. Eye contact should be medical consulted immediately. For further information please refer to Material Safety Data Sheet (MSDS).

Legal Liability

The technical recommendations in this product data sheet are based on the experimental studies performed on reference concrete mixtures designed in the R&D laboratories of SERKEFT. The results may not be applicable to different concrete mixtures produced with different materials than the ones used in the experiments in SERKEFT. All customers and users are required to determine the appropriate SERKEFT products for their intended use and to test the suitability of SERKEFT product for their application. Please contact SERKEFT for the appropriate product selection and usage details. SERKEFT is not responsible for the improper usage of the products.

SUPER X412

LIGNOSULFONATE BASED

AIR ENGRAVING CONCRETE

DRYING RETARDER

WATER REDUCING

your innovation

solution partner

REVISION DATE :02/06/2022

REVISION NUMBER: 19/04/2023

Product Definition

SUPER X 412 isa Modified Lignosulfonate based chemical admixture presenting high range water reducing and super plasticizing in Portland cement mixtures

Uses

SUPER X 412 is recommended for use in the applications and purposes below.

• To increase the flowability and workability of concrete without increasing water content.

• To decrease slump-loss and enhance the workability.

• Ready-mixedconcrete applications.

• Concretes designed for sections of closely spaced and congested reinforcing steel.

• Drying retarder in hot weather

• For concrete transported over long distances

Advantages and Properties

- is a Modified Lignosulfonate based chemical admixture designed for enhancing workability of concrete.

- Has water-reducing and plasticizing on concrete. Adding SUPER X 412 in an appropriate dosage to concrete without reducing water content can produce a mixture with higher slump.

- Works on the mechanism of lowering zeta potential leading to electrostatic repulsion to separate cement particles from flocculation. This mechanism makes SUPER X 412 an effective dispersant to obtain enhanced flowability even in low water to cement ratios.

- Presents satisfactory workability retention performance.

- Compatible to use concrete mixtures containing different types of mineral admixtures such as ground granulated blast furnace slag, fly ash and silica fume.

- Reduces the permeability and enhances the durability of hardened concrete.

- Improves the ultimate strength of concrete.

- Does not contain any compounds that may cause corrosion of reinforcing steel.

Application Details, Suggestions and Warnings

- should be added to the mixing water. As an alternative way, it can be mixed with the 1/3 of the mixing water and added to fresh mixture prepared by the remaining of mixing.

- water. In case of the direct addition to the fresh mixture's described, an additional mixing time should be applied. SUPER X 412 should not be added to the dry mixture.

- As the dosage of the chemical admixtures is greatly influenced from cement type, properties of the concrete ingredients and mix design, it is recommended that the optimum dosage of admixture should be determined on trial batches.

- SUPER X 412 is known to be compatible with normal Portland cement types described in EN 197-1.In addition, it can be used in concrete mixes containing mineral admixtures such as silica fume, fly ash and ground granulated blast furnaces lag. However, since the presence of mineral admixtures in the mixture greatly influences the required dosage of the admixture for a specified target or performance, the optimum dosage of SUPERX412 should be determined on trial batches.

- There is no known incompatibility with the other type of chemical admixtures and can be used with the others in the same mixture. In case of the combined usage, the different types of chemical admixtures should not be mixed together and be used separately. Please contact department of SERKEFT for further information.

- SUPER X 412 has a significant level of retardation effect and the extend of retardation increases as the dosage increases. Freshly placed concrete should be properly protected and cured to avoid plastic shrinkage cracking.

- SUPER X 412 is not compatible with polycarboxylate based chemical admixtures. There is no known incompatibility with the other type of chemical admixtures and can be used with the others in the same mixture. In case of the combined usage, the different types of chemical admixtures should not be mixed together and be used separately. Please contact R&D department of SERKEFT for further information.

Cleaning of Tools

- Concreting tools contact with super x412 can be easily cleanedwith water.

Packaging

25 kg Plastic drum

1000 kg IBC

Bulk Delivery

Recommended Dosage

The recommended dosage of SUPER X 412 is between 0.5 % - 1.5 % of the weight of binding (cement+ mineral admixture) material (0.5 to 1.5 kg for 100 kg cement). It is recommended that the optimum dosage of SUPER X 412 should be determined on trial batches. Overdose may cause segregation and excessive increasing setting time. Please contact SERKEFT chemical for technical support.

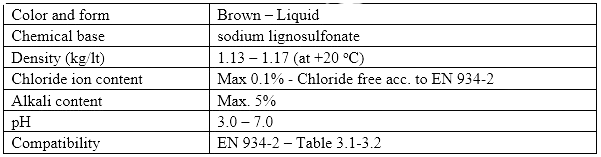

Technical Properties

Storage and Shelf Life

Shelf life of SUPER X 412 is 12 months when stored in its original package and recommended stored conditions. SUPER X 412 should be stored in dry conditions between +5 ℃ and +35 ℃. It should be protected from direct sunlight and frost

Security and Health

In case of contact with skin, wash with clean water. In case of contact with eye, wash with clean water. Eye contact should be medical consulted immediately. For further information please refer to Material Safety Data Sheet (MSDS).

Legal Liability

The technical recommendations in this product data sheet are based on the experimental studies performed on reference concrete mixtures designed in the R&D laboratories of SERKEFT. The results may not be applicable to different concrete mixtures produced with different materials than the ones used in the experiments in SERKEFT. All customers and users are required to determine the appropriate SERKEFT products for their intended use and to test the suitability of SERKEFT product for their application. Please contact SERKEFT for the appropriate product selection and usage details. SERKEFT is not responsible for the improper usage of the products.

SERKEFT Chemical has taken its place among the few reliable companies in the sector with ISO 9001:2015 Quality Management System, and CE-certified products. In addition, there is a patent application for 3 raw materials used in the concrete chemicals developed by SERKEFT Chemical itself. Every single thing result from the necessity, and the necessity finds its value in SERKEFT Chemical

SUPER X 412

High-Range Water Reducing/Drying Retarder/ Super plasticizing/Hardening Accelerating Chemical Admixture for concrete

HEZX933 Drying Retarder (Super plasticizing Admixtures) is a polycarboxylate based high range water reducing / super plasticizing and hardening accelerating type of chemical admixture designed for applications which high workability and early and ultimate strength development are simultaneously needed.

Is recommended for use in the applications and purposes below.

- Concreting in summer season

- Concrete to be transported to long distances.

- Ready-mix concrete production requiring high workability.

- Concrete production in low water to binder ratio and high workablity class.

- Concreting works requiring high early and ultimate strength.

- Heavily reinforced structural elements such as shear walls, columns and beams.

- Wet-mix shotcrete applications.

Advantages and Properties:

- Provides an effective dispersion of cement particles due to the electrostatic repulsion mechanism,

- HEZ X933 is a chemical admixture which, without affecting the consistency, permits a high reduction in the water content of a given concrete, or which, without affecting the water content, increases the slump/flow considerably, or produces both effects simultaneously.

- As compared to reference concrete, usage of HEZ X933 in an appropriate dosage Increases the workablity of fresh concrete and provides easiness in mixing, transporting, placing and vibration works.

- Enhances the strength and durability of hardened concrete by achieving the target workability class in lower water to binder ratlos.

- Improves the early and ultimate strength of hardened concrete as compared to a reference concrete in the same consistency without chemical admixture.

- Reduces demolding time as compared to reference concrete without chemical admixture

- Reduces shrinkage and creep of concrete.

- Does not contaln chloride or any other substances that may cause corrosion

- Provides advantage in concretes to be transported to long distances.

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

HEZ X 933

HEZ X 106

High-Range Water Reducing / Super plasticizing / Hardening Accelerating Chemical Admixture for Concrete Is a polycarboxylate based high range water reducing / super plasticizing and hardening accelerating type of chemical admixture designed for applications which high workability and early and ultimate strength development are simultaneously needed.

Is recommended for use in the applications and purposes below.

- Ready-mix concrete production requiring high workability.

- Concrete production in low water to binder ratio and high workability class.

- Concreting works requiring high early and ultimate strength.

- Heavily reinforced structural elements such as shear walls, columns and beams.

- Wet-mix shotcrete applications.

- Concreting applications requiring early demolding.

- Precast concrete industry.

Advantages and Properties:

- CAST CT789 is polycarboxylate based, high-range water reducer / super plasticizer type of chemical admixture designed for making flowable concrete. Due to its specially designed and optimized chemical structure it provides very effective dispersion of cement particles and prevents the flocculation.

- Provides high early and ultimate strength.

- Provides high workability retention performance.

- CAST CT789 is chemically a polymer with backbone and side chains. It is adsorbed on the surface of the cement particles and provides excellent dispersion of the cement particles by steric effect of its side chains. This mechanism makes CAST CT789 a very effective dispersant to obtain self-compact ability in very low water to cement ratios.

- A water reduction up to 40% by satisfying the target workability can be obtained through the appropriate usage of CAST CT789 This significant amount of water reduction and decreased water to cement ratio results in increased early strength gain, increased ultimate strength, enhanced durability and the other beneficial properties associated with low water to cement ratio such as decreased chloride-ion penetration.

- Provides significant increase in workability without increasing the quantity of mixingwater and hence procures considerable convenience in mixing,transporting, placing and compaction of fresh concrete.

- Does not contain any compounds that may cause corrosion of reinforcing steel.

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

CAST CT 789

your innovation

solution partner

HYPER W695

High-Range Water Reducing / Super plasticizing Chemical Admixture for Concrete.

Product Definition:

Is a polycarboxylate based, high-range water reducer / superplasticizer type of chemical admixture for concrete.

permits a high reduction in water content of a given concrete compared to a reference concrete mixture without chemical admixture

Increases slump/flow of the mixture having the same amount of mixing water.

HYPER W695 is recommended for use in the applications below.

> Heavily reinforced concrete structural sections requiring concrete mixtures with high workability and consistency classes.

> Ready-Mixed concrete production requiring high plasticity and less workability loss

> In applications requiring broad-range concrete design for strength enhancement, improved workapilty and minimizing cement conlent.

Advantages and Properties:

/ HYPER W695 provides more homogeneous distribution of cement particles mainly due

to the steric effects of its side chains.

/ Reduces the agglomeration of cement particles and improves the flow ability.

Provides significant increase in workability without increasing the quantity of mixing water and hence procures considerable convenience in mixing, transporting, placing and compaction of fresh concrete.

/ Improves the strength and durability by ensuring that the specified target consistency is achieved with lower water to binder ratios.

/ Provides high workability even in low water to binder ratios.

/ HYPER W695 is an appropriate type of admixture for concrete design aiming at reducing cement content to the allowed limits. High level of plasticizing capacity of HYPER W695 enables more economical concrete design with less cement content.

Concretes designed in this way may be beneficial with their lower shrinkage and heat of hydration characteristics.Enhances early strength as compared to a reference mixture having the same level of consistency without chemical admixture.

/ It is non-chloride admixture and does not contain any compounds that may cause corrosion of reinforcing steel.

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

Hyper Blocks®

your innovation

solution partner

Chemical Admixture for Zero-Slump or Semi-Dry Concrete.

Product Definition:

Hyper Block SD is a specially designed chemical admixture to increase compact ability of zero-slump or semi-dry concrete mixtures used for cementitious curbstone and paver block production.

Use:

Production of concrete blocks, curbstone and paver bricks.

To increase the compact ability of semi-dry mixtures with zero or very low slump.

In applications requiring broad-range concrete design for strength enhancement, improved workability and minimizing cement content.

Advantages and Properties:

/ Hyper Block SD is a lignosulfonate based chemical admixture designed for enhancing compact ability of zero or very low-slump semi-dry concrete mixtures for curbstone and paver block production.

/ Provides better dispersion of cement particles by electrostatic dispersion mechanism and enhances the compact ability of the mixture without decreasing the cohesiveness.

/ Increases the degree of compaction of low-slump mixtures.

/ Hyper Block SD decreases the vibration time in cementitious curbstone and paver block production. Reduced vibration time increases the mould life and provides economy.

/ Decreases the compaction time in semi-dry concrete mixtures compressed by machinery.

/ Enhances the surface appearance and texture properties.

/ Hyper Block SD is compatible with different types of mineral admixtures such as ground granulated blast furnace slag, fly ash and silica fume.

/ Increases the early strength.

/ Decreases the broken or defective product ratio in cementitious curbstone and paver block production.

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

your innovation

solution partner

SUPER W411

SUPER W411 Water Reducing / Super plasticizing / Chemical Admixture for Concrete Is a modified sulfanate based, chemical admixture presenting normal and

super plasticizing performance depending on the usage dosage.

Uses:

Super w411 (Plasticizing Admixtures) is recommended for use in the applications and purposes below.

> For improving workability and placing of conventional fresh concrete.

>For improving placing of concrete designed for slabs.

> Ready-mixed concrete production.

> Normal reinforced concrete elements such as column, shear wall and beam.

Advantages and Properties:

It is a modified sulfonate based general purpose chemical admixture designed to increase the workability of fresh concrete without increasing its water content.

Provides advantage to the concrete mix to be transported to long distances.

Provides the maximum compact ability in fresh concrete with less vibration energy.

Enhances the durability and the ultimate strength of hardened concrete by achieving

the target workability class in lower water to binder ratios.

Super w411is an appropriate chemical admixture to use in mixtures containing mineral

admixtures such as silica fume, fly ash and ground granulated blast furnace slag.

Does not contain chloride or any other substances that may cause corrosion

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

HEZ C785

your innovation

solution partner

High-Range Water Reducing / Super plasticizing / Hardening Accelerating Chemical Admixture for Concrete Is a polycarboxylate based high range water reducing / super plasticizing and hardening accelerating type of chemical admixture designed for applications which high workability and early and ultimate strength development are simultaneously needed.

Is recommended for use in the applications and purposes below.

- Ready-mix concrete production requiring high workability.

- Concrete production in low water to binder ratio and high workability class.

- Concreting works requiring high early and ultimate strength.

- Heavily reinforced structural elements such as shear walls, columns and beams.

- Wet-mix shotcrete applications.

- Concreting applications requiring early demolding.

- Precast concrete industry.

Advantages and Properties:

- Provides an effective dispersion of cement particles due to the electrostatic repulsion mechanism.

- HEZ C785 is a chemical admixture which, without affecting the consistency, permits a high reduction in the water content of a given

- concrete, or which, without affecting the water content, increases the slump/flow considerably, or produces both effects simultaneously.

- As compared to reference concrete, usage of HEZ C785 in an appropriate dosage increases the workability of fresh concrete and provides easiness in mixing,

- transporting, placing and vibration works.

- Enhances the strength and durability of hardened concrete by achieving the target workability class in lower water to binder ratios.

- Improves the early and ultimate strength of hardened concrete as compared to a reference concrete in the same consistency without chemical admixture.

- Reduces demolding time as compared to reference concrete without chemical admixture.

- Reduces shrinkage and creep of concrete.

- Does not contain chloride or any other substances that may cause corrosion

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

Nano Retarder

your innovation

solution partner

Set Retarder Chemical Admixture for Concrete

Nano Retarder is a set retarding chemical admixture specially designed for use in situations where setting time of fresh concrete should be intentionally extended for a long time.

Uses:

Nano Retarder is recommended for use in the applications and purposes below.

- Any type of concrete operation requiring extended setting time of fresh concrete.

- Continuous and large volume concreting operations.

- Mass concrete applications.

- Concrete operations that cold joint formation is undesirable.

- In case of fresh concrete transportation to very long distances.

- Concrete works requiring extended time for placing, vibrating and surface finishing operations

- Concrete operations requiring re-vibration.

- Operations in hot weather conditions.

Advantages and Properties:

- Nano Retarder significantly extends the initial and final setting time of cement. It is suitable for use in all concreting operations where the fresh concrete

- must be remained in plastic stage for long time.

- Provides easiness in large-volume and continuous concreting operations requiring advanced planning in production, transportation, pumping, placing,

- vibrating and surface finishing of fresh concrete.

- Provides advantage in continuous mass concrete production by keeping the first layer concrete still capable of deforming as the upper layers successively

- placed in a long time.

- Reduces cold-joint formation risk in layered mass concrete production.

- Does not affect the ultimate strength of retarded concrete

- Does not contain chloride or any other substances that may cause corrosion

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

Anti-freezeXC102

your innovation

solution partner

Super plasticizing Anti-freeze and set accelerating admixture for concrete and mortar.

Anti-freeze XC102 is a calcium nitrate salt based with organic materials. Set accelerating/Anti-Freeze / plasticizer concrete admixture is suitable

for cold weather conditions that increases set acceleration and early strengths by increasing the reaction between water and cement especially at the start of set.

Uses:

- Protects fresh concrete from frosting action by reducing the freezing point of mixing water.

- Accelerates the hydration of cement even in temperature levels close to freezing point.

- Shortens the required time to obtain a minimum strength level of 5 MPa for avoiding frost damage at early ages.

- Increases strength gain rate and early strength.

- Does not contain chloride or any other substances that may cause corrosion.

Advantages and Properties:

- Nano Retarder significantly extends the initial and final setting time of cement. It is suitable for use in all concreting operations where the fresh concrete

- must be remained in plastic stage for long time.

- Provides easiness in large-volume and continuous concreting operations requiring advanced planning in production, transportation, pumping, placing,

- vibrating and surface finishing of fresh concrete.

- Provides advantage in continuous mass concrete production by keeping the first layer concrete still capable of deforming as the upper layers successively

- placed in a long time.

- Reduces cold-joint formation risk in layered mass concrete production.

- Does not affect the ultimate strength of retarded concrete

- Does not contain chloride or any other substances that may cause corrosion

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

PLAST TR 607

your innovation

solution partner

Waterprooting Chemical Admixture for concrete.

Product Definition :

- Waterproofing Admixture PLAST TR607 is a modified lignosulphonate based chemical admixture reducing the surface absorption and water permeability

- of concrete. PLAST TR607 enhances the flowability of fresh concrete.

Waterproofing Admixtures PLAST TR 607 is recommended for use in the applications below :

- To reduce the low-pressure or unpressurised water permeability of concrete.

- Swimming pool, open channel and tunnel segment constructions.

- Concrete designed for wastewater treatment plants, dams, culverts and water reservoirs,

- Concrete elements under the high risk of water absorption by capillary suction.

- To reduce water ingress in tidal and splash zone of water structures.

Advantages and Properties:

- Enhances the impermeability of concrete by reducing the size, number and

- continuity of capillary pore structure of the cement paste.

- Enhances durability due to the decreased water permeability of the

- cementitious paste.

- Improves the workability without increasing the water content.

- Reduces shrinkage.

- Does not contain chloride or any other substances that may cause corrosion

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

Shot IT 845 Sprayed Conerete Admixture

your innovation

solution partner

Alkali-Free Set Accelerator Chemical Admixture for Wet-Mix Sprayed Concrete.

Product Definition :

- SHOT IT 845 is an alkali-free set accelerator type of chemical admixture particularly

- designed for use in wet-mix sprayed concrete (shotcrete) applications.

Uses:

- Wet-Mix Sprayed Concretes sprayed concrete applications.

- Concrete jacketing, lining and overhead works in tunnel constructions

- Concrete operations for rock, soil and slope stabilization.

- High quality sprayed concrete applications for strengthening purposes.

- High early strength sprayed concrete applications.

Advantages and Properties:

- Significantly shortens the setting time and increases the strength gain rate of concrete through its special design. It is an appropriate chemical admixture for sprayed concrete applications.

- Alkali-free.

- Appropriate for glass fiber reinforced sprayed concrete that may be negatively affected from high alkaline environment.

- SHOT IT 845 enhances the productivity and shortens the construction time of sprayed concrete applications by increasing the cohesion of the mix, shortening the setting time and increases early strength of sprayed concrete.

- Reduces the loss of material by rebound.

- Reduces the ultimate strength loss.

- Compatible with the other types of chemical admixtures (i.e., air entraining admixtures).

- Improves the bond between rock surface and sprayed concrete layer as well as old and new sprayed concrete layers.

- Does not contain chloride or any other substances that may cause corrosion.

DOSAGE

By Weight - 1.0 to 1.3 kg per 100 kg of cement

The dosage rates given above are for typical usages. For special concrete mixtures cases

Consult (SERKEFT TECHNICAL SUPPORT DEPARTMENT)

FIBER Q606

your innovation

solution partner

Macro-Synthetic Monofilament Copolymer Fiber Q606 is a monofilament macro-synthetic copolymer fiber for reducing

crack density and width, preventing plastic shrinkage and plastic settlement crack risk in concrete. Fiber Q606 is used by adding to fresh concrete mixture.

Uses:

- Large-area slab-on-grade concrete, concrete slab coatings

- Industrial slabs.

- Parking lots and loading areas.

- Precast panel, facade and wall element production.

- Concrete canal, precast concrete saddle and water structures.

- Agricultural structure slab and ground concretes.

Advantages:

- Reduces plastic shrinkage and settlement crack risk

- Increases the energy absorbing capacity of concrete

- Enhances flexural performance of hardened concrete

- Improves durability of concrete by reducing and limiting cracks

- Improves fire resistance of concrete

- Increases impact resistance of concrete

- Improves the cohesiveness of fresh concrete, reduces bleeding.

- Reduces the amount of steel mesh reinforcement

DOSAGE

Nano CA TR 404 for Quality Improvers

your innovation

solution partner

- Nano CA TR 404 series products significantly improve cement performance & quality by increasing early and long-term compressive strengths and also provide benefits as grinding aids.

- Enhances the quality of all types of cements and improves cement performance thus gives opportunity to produce higher class of cement to meet market demands.

- Increases grinding efficiency also give chance to add higher level of SCM's -lower clinker factor- therefore provides cost saving

Nano Grind I 100 for Grinding Aids:

- Nano Grind TR 100is a new generation grinding aid for the cement production.

- Nano Grind TR 100 - 150 significantly improve grinding process efficiency and provide benefits in terms of operational costs.

- Improves the grindability of the clinker by reducing the specific energy consumption. Therefore, increases the efficiency of the plant (tons per hour) and produc

- Provides the desired cement fineness with a shorter grinding time and reduces the re-agglomeration of cement particles during production.

- Reduces coating and increases the separation efficiency. Nano Grind TR 100 series products increases the powder fluidity (reduce pack-sel) and provides easy discharge from the storage silos. Therefore, provides ease of movement for pneumatic conveying systems.

- Nano Grind TR 100 PC series products have been developed by using SERKEFT Polycarboxylate Raw Materials after long-term &D activities.

- PC based grindings aids provides increase in cement mill output besides that significantly improves the viscosity of cement paste and has a significant effect on the particle size distribution of the cement.

DOSAGE

Nano MIC TR200 MAneral Additives

Nano MCR TR200 series products have been developed for industrial minerals grinding process in order to increase production volume and provide cost saving.

Improves grindability, reduces pack set, agglomeration, coating and increases flowability.

They can be used for grinding of calcite, barite, dolomite, lime and ceramics

Connect to Us

Ibrahim al-Khalilroad , Zakho , Iraq